Why Appalachia Is Ready for a Reuse Corridor

Written by: Jacob Hannah, Coalfield Development Corporation

TRADITIONALLY, the notion of “sustainability” as we know it today was being humbly pioneered here in Appalachia. We can all recall stories of how the “grandparent generation” canned and dried their excess food, planted their own gardens, made their own tools, repaired them when they broke, and used “hillbilly ingenuity” to transform materials that we today would call “useless” into innovative resources. Fats into soaps, food into fertilizer, furs into fashion. I can still recall stories my mom would tell me of Mabel Sturgill May who lived in Marrowbone, West Virginia:

“She was a good steward of her resources, well she had to to survive, and she had this ‘paring knife’ for peeling fruits and vegetables that she had used and resharpened so much that it was razor thin and had a worn out gap in the middle. Which actually made it really effective and easy to use.”

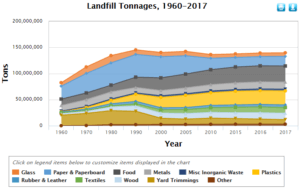

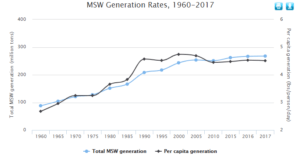

Fast forward one or two generations, and we have a different vocabulary: “landfill-destined” is a term used to describe a vast range of “end-of-life” resources that still hold innate value, but lack the necessary systems to extract or capture it. Electronic-waste, cardboard, plastics, compostables, mattresses, construction materials, batteries, and medical equipment are just a few examples. Increasing tariffs and shifting economic factors have only increased the amount of waste we accumulate and dispose of in America, and according to the EPA, that amount isn’t going down.

The total generation of municipal solid waste (MSW) in 2017 was 267.8 million tons (or 4.51 pounds per person per day). But only approximately 67 million tons were recycled and 27 million tons were composted.

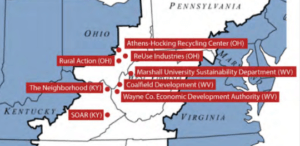

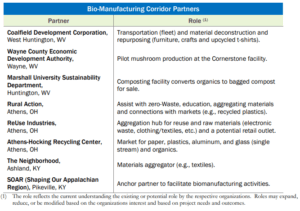

OPERATIONALLY, this is where our pilot ReUse Corridor is hitting the ground running. So what is the ReUse Corridor? Throughout central Appalachia, there are organizations of makers and upcyclers that are reintegrating the traditional values of reuse into their business models, and it’s creating jobs and financial returns. These organizations aggregate and cross pollinate resources that have innate value that can be captured and transformed. Spanning Kentucky, West Virginia, and Ohio, the corridor consists of a logistics system that connects communities that have either a supply or demand for materials like e-waste, cardboard, plastics, compostables, mattresses, construction materials, batteries, and medical equipment.

Powered by a technical assistance grant from the Appalachian Regional Commission (ARC), and a Solid Waste Management grant from the USDA Rural Utilities Service, the ReUse Corridor team is simultaneously laying the groundwork for implementing material pick-up events throughout the region while also consulting with a 3rd party contractor for developing five key deliverables:

- Project Facilitation: MSW Consultants will capture and organize information including capabilities, materials, locations, and pertinent data that will influence the selection of preferred implementations strategies for diverted materials.

- Market Analyses: MSW Consultants will research the region’s re-use markets including ReUse Corridor Partners and private sector opportunities. We will assess markets with the greatest potential for reuse, upcycling, and bio-based manufacturing.

- Preliminary Financial Analysis: MSW will develop initial financial projections and marketing strategies for at least five bio-based/upcycling/reuse business ideas.

- Material Flow Logistics: Develop recommendations pertaining to the flow of materials across the various sites in the Bio-manufacturing corridor and distribution of materials and products to urban markets.

- Operations Pro-forma: Based on the selected preferred materials and plans, MSW Consultants will estimate required equipment and implementations costs. Furthermore, MSW Consultants will estimate projected economic impact, jobs created, and materials diverted from landfills.

Logistically, the corridor is mobilized through ReGear Appalachia, a social enterprise of Coalfield Development that focuses on reskilling coal-impacted folks on obtaining their CDL training and future employment through their workforce development model. Originally, these pick-up events were to be held throughout the corridor once a month for 5 months beginning in March 2020; however, in the interest of public safety in regards to potential public exposure to COVID-19, the pick-up schedule has pushed back temporarily and is expected to operate shortly.

ECONOMICALLY, it comes down to economies of scale. By the year 2024, the market for recyclables is expected to grow to about $377 billion dollars. The opportunity for economic impact in ReUse exists within every supply chain, not just organizations focused towards addressing the issue directly. Everyday businesses spend thousands of dollars in aggregation, sorting, transportation, disposing, landfill fees, and labor.

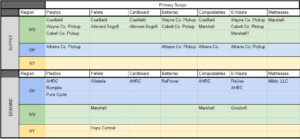

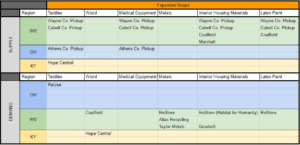

The table above represents the primary and expanded scopes for the supply and demand of the ReUse Corridor. These organizations represent a diverse mix of legal structures in the region that can and have harmoniously collaborated to satisfy market needs. Similar to municipality-funded pick-up events, this corridor will use grant funding to help connect these resources to the regional supply chains that need them, stimulating local economies and reducing waste-related costs.

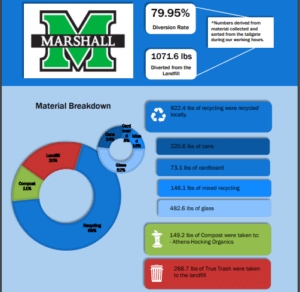

CULTURALLY, Appalachia is ready for a reawakening like this, a return to sustainable lifestyles and responsible lifestyles. And understanding was truly exemplified by a recent ReUse event: the Ohio Bobcats vs. the Marshall Thundering Herd rivalry is often referred to as a “friendly rivalry.” In other words, we compete hard but we respect each other, like each other, and root for the other when they’re not playing us. For the 2019 match up, this friendly rivalry extended off the field. Partners from Zero Waste Event Productions LLC, based out of none-other than Athens, OH, teamed up with the Marshall University Office of Sustainability to bring recycling options to the tailgaters of the game.

“Oh that’s so great, I’ll take two bags for our group!” This was the common phrase of the day heard across the parking lot, as hundreds of tailgaters gladly took special bags for recycling their glass, cans, and plastics. Volunteers coordinated by Amy Parsons-White (Marshall’s Sustainability Director) worked hand-in-hand with the Ohio-based “Zero Waste” team to reach out to every tailgate within their radius. It wasn’t uncommon to hear “Wait really? That’s so awesome, I’m glad Huntington is doing this!”

This collective collaboration didn’t end there. The Wendy’s next to our sorting station gave our teams water for rehydrating and for rinsing our sorting station, along with vouchers for meals to eat there as well! By the end of the day, the blue recycling bags could be seen across the lot, later to be stacked three rows high. Bikes, trucks, and volunteers worked together to reach out into every alley and collect the now-full bags. “Where’s my recycling guy?” called out one tailgater.

With the mobile sorting station on site, folks would walk by and smile as thousands of items were sorted and bagged for repurposing, diverting tons of materials from the landfill. People came up to say things like “Can we get you guys a drink? We want to support this and help out. We’ve really wanted something like this for a long time.” Others helped collect the bags themselves. The entire day was a snapshot against the negative stigmas towards Appalachians, and a testament to the greater need for more opportunities for participation in keeping our Jewel City beautiful.

This is the sort of cross-state, cross-institution collaboration that gives hope for central Appalachia. When we come together, when we share our resources, we can compete with any other region in the country. By getting past our differences we can create more healthy, vibrant, sustainable communities for our children and grandchildren. We got one small slice of that future vision in the parking lot of Joan C. Edwards stadium.